Maintain & Upgrade Irrigation Systems to Ensure Water-Efficiency

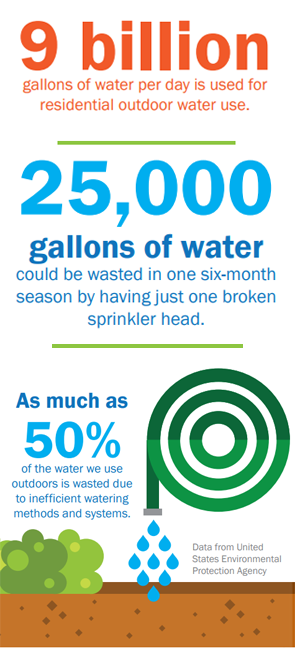

Research shows that landscape irrigation uses 50% or more of the water provided by many utilities. Without proper irrigation system maintenance, much of that water is lost as it never reaches its intended source due to runoff, evaporation, and deep watering below the root zone. Poorly maintained irrigation systems are also responsible for broken equipment, costly leaks, unsightly damage to landscapes, and higher utility bills.

Research shows that landscape irrigation uses 50% or more of the water provided by many utilities. Without proper irrigation system maintenance, much of that water is lost as it never reaches its intended source due to runoff, evaporation, and deep watering below the root zone. Poorly maintained irrigation systems are also responsible for broken equipment, costly leaks, unsightly damage to landscapes, and higher utility bills.

Irrigation system issues are caused by many factors such as damage from lawn equipment, improper winterization, or bad installations that cause leaks and other serious problems. Irrigation systems need regular maintenance to keep them working efficiently year after year. At the very least, irrigation inspections should be performed twice seasonally. Once when the system is first turned on at the beginning of the season and again halfway through the season. Ideally, irrigation systems should be checked on a monthly basis. A thorough, routine inspection of your customer’s irrigation systems is a great addition to your maintenance packages offered to ensure consistent water efficiency.

Following are some common issues found in irrigation system inspections and how they should be fixed to ensure an efficient system:

1. Broken Equipment & Leaks

1. Broken Equipment & Leaks

The most obvious and common issue is when equipment is broken or leaking. Breaks and leaks can occur as a result of weather damage (freezing and thawing), damage from shovels and other sharp tools, lawnmowers, vandalism, tree roots, improperly installed heads, and normal aging of the system. Leaks from valves and pipes may be large and very obvious. Smaller leaks may not show up immediately and will require some detective work. Broken or leaking equipment will allow water to leak out of the system resulting in runoff while offering nothing to your landscape and increasing your water bill.

The Fix:

Inspect the following irrigation components visually to ensure proper working condition:

– Sprinkler Heads

– Main & Lateral Line

– Valve Box

Repair all broken heads, valves, and piping. Installing heads on a swing joint allows the head to “float” in the soil and reduces the damage that can result from lawn mowers and other heavy objects.

2. Misaligned Equipment

Tilted Heads:

Over time, sprinkler heads settle and tilt due to natural compaction of soil, foot traffic, and lawn maintenance. This results in uneven distribution of water resulting in brown spots and runoff.

Sunken Heads

Sunken sprinkler heads settle due to natural compaction of soil. This will result in stems that cannot popup above the grass and frequently causes uneven distribution of water, misting, brown spots, and runoff.

The Fix:

To repair tilted or sunken heads, remove turf surrounding sprinkler (be careful not to hit the lateral line) then lift and straighten the head by packing soil under and around until it is level with and perpendicular to the ground. Then replace your sod pieces back in place around the head and water them to encourage reestablishment.

3. Mixed Zones

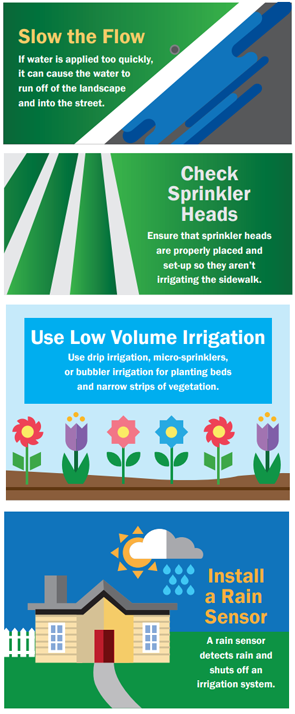

Mixed areas exist when a rotor, rotary, and/or fixed spray heads operate together on a given zone. Spray heads are designed to emit an average of 50% more water than rotor heads. Therefore, all sprinkler heads require different operating pressures and belong in separate zones from one another. Mixed zones will create overly wet areas or excessively dry areas.

The Fix:

Mixed areas exist when a rotor, rotary, and/or fixed spray heads operate together on a given zone. Spray heads are designed to emit an average of 50% more water than rotor heads. Therefore, all sprinkler heads require different operating pressures and belong in separate zones from one another. Mixed zones will create overly wet areas or excessively dry areas.

4. Blocked Heads

Common Causes of Blocked Heads:

– Overgrowth of Vegetation

– Changes to Landscape and Not the Sprinkler System

– Poorly Placed Heads

If sprinkler heads are being blocked, water is not reaching the intended area. This can also lead to uneven spray pattern and brown grass.

The Fix:

Fix a blocked sprinkler head issue by trimming back overgrown vegetation, moving the head with blocked spray pattern, or, if the area is not suited for watering by a sprinkler head, consider replacing the turf with mulch, rock, or water-conserving plants.

5. No Check Valves

5. No Check Valves

After a system is turned off, water may drain out of sprinkler heads that are at lower elevations. Check valves lock water in the lateral line and result in quicker start up times and no run off after the system turns off.

The Fix:

Install heads with check valves to eliminate water loss from the system, and prevent excess wear on the system pipes. Several types and brands of heads come with pre-installed check valves. If a check valve is necessary, simply replace the whole head.

6. Inappropriate Nozzle/Spray Pattern

Inappropriate spray patterns originate in one of two ways:

1. Throw distance (radius) of the nozzle is too far.

2. Arc (angle) of the nozzle is not appropriate for the area to be watered.

Example: A spray head with a 180 degree fixed spray pattern in an area that only requires 160 degree of spray.

The Fix:

Use variable arc nozzles in situations where a custom arc is needed. Use the radius reduction screw, if you need to adjust distance, but be careful not to adjust more than 20%. Use the hunter key to adjust rotor heads.

7. Clogged Nozzle

A clogged nozzle is caused when debris in the system gets stuck in the nozzle or the filter of a spray head. Sometimes, a dirty water source, or simply normal wear and tear will cause issues. Clogs may be caused by dirt, sand, roots, plastic, etc. Clogged heads can cause uneven distribution of water resulting in brown spots.

The Fix:

To fix a clogged nozzle, screw the nozzle off of the spray head. Be sure to hold onto the stem of the head or clamp it to prevent it from dropping back into the body of the head. Take the filter out of the stem and wash out any debris in the filter or the nozzle. Put the clean filter back into the stem and screw the nozzle back on. Adjust the spray pattern to ensure that water is spraying onto the turf. Sometimes, it may be necessary to improve water system filtration.

8. Improper Pressure

High Pressure:

Install a pressure regulator after the backflow preventer, before the zone valves, feeding the whole system.

The Fix:

If pressure is high in the entire system:

Install a pressure reducer on the pipe, before the valves, feeding the whole system.

If pressure is high on one zone:

Install pressure regulator on the zone valve. You can also install heads with pressure regulated stems.

Low Pressure:

Low pressure does not allow the heads to pop up fully resulting in poor coverage. Low pressure could be a sign of an underground leak.

The Fix:

Check static pressure at site. Check with your local water district about main line pressure issues.

If pressure is low in one area of a given zone:

Check for leaking heads or potential underground leaking lines.

If the zone has too many heads, consider redesigning the system to efficiently water the area with fewer heads.

9. Overspray

Overspray is caused when sprinkler heads are improperly adjusted, and are set to spray on surfaces not requiring irrigation. Examples of such areas could be sidewalks, driveways, mulch or rock beds, or even fences. Overspray results in runoff and thus excessive water waste. Often times, overspray that reaches gutters will pollute ground water with pesticide and fertilizer.

The Fix:

Fix overspray issues by adjusting system pressure, adjusting nozzles, or installing the proper size and type of nozzle.

10. Poor Spacing

For adequate coverage, use head to head spacing. Heads that are spaced too far apart create dry spots of brown grass.

The Fix:

To fix poor spacing, change nozzles, add heads, or alter the spacing of heads.

Irrigation maintenance is one of the most important factors in reducing water waste in the landscape. In addition, a well-maintained and properly adjusted system is essential for a healthy, beautiful, landscape. Paired with a well-designed and installed smart irrigation system, and a water efficient plant layout your next job will be perfectly optimized for water efficiency and sustainability.

To learn more about irrigation maintenance and installation tips or to explore other industry resources visit our Knowledge Center. If you are an irrigation professional in the Colorado or Wyoming area and would like to partner with CPS distributors to help your business grow, visit our Become A Customer page.